We are proud to announce that Runfold’s Operations Director Scott has been shortlisted for mentor of the year! Not only that but Runfold Plastics has been shortlisted for the award of Best Apprentice Employer (SME).

News

Connor Cooper has been shortlisted for apprentice of the year

Runfold Plastics are proud to announce that another of our brilliant apprentices have been shortlisted for PETA’s Apprentice Of The Year award!

Dean’s 40th Anniversary

This last week has completed the amazing 40th year of service at Runfold Plastics from our longest serving operator Dean!

Happy new year to all of our customers and suppliers!

At Runfold we are proud to share the certificate of our newest accreditation – ISO 45001!

Runfold Plastics Provide New Solution to Key Electrical Equipment Supplier

We manufacture a range of custom dip moulded protective shrouds for transformers and switchgear.

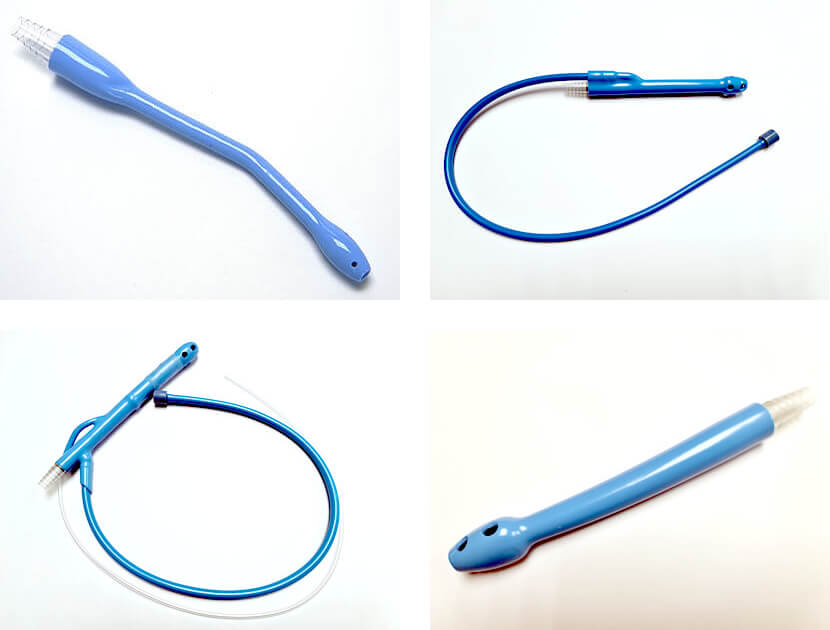

Runfold Plastics Now Supply Enema Tips Directly to NHS

Supplying a range of quality enema tips directly to the NHS.

PETA Awards Finalists!

Finalists for PETA’s Mentor of the Year and Best Apprentice Employer (SME) awards.

Over 10000KG Reduction of CO2 in First 3 Weeks of New Solar Array at Runfold Plastics

In the first 3 weeks of our solar array coming online it has already made a contribution to the reduction of CO2 output by over 10000 KG.

Positive Energy at Runfold Plastics

We’re always looking at efficient ways to invest in our profitable future, securing first class custom dip moulding services for our vast array of customers.

Custom Dip Moulding Gaiters for Dumper Trucks and all Heavy Machinery

Manufacture and supply custom dip moulded gaiters to the off road vehicle and heavy machinery market.